Fusion Stone

Brick and stone remain valued for their durability and timeless appeal. From heritage buildings to fireplaces, masonry continues to signal quality and permanence.

Because masonry requires skilled labour and specific weather conditions, projects can face extended timelines and higher costs. That has created growing demand for alternatives that preserve the look of stone or brick while offering faster, more flexible installation. Mechanically fastened systems fill this need by combining authentic aesthetics with efficiency.

How Mechanically Fastened Systems Work

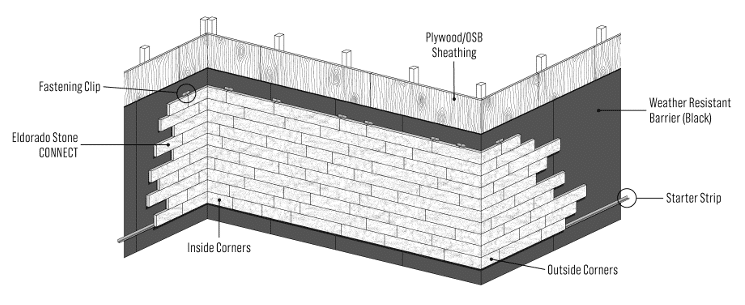

A mechanically fastened system creates the appearance of traditional masonry but fastens lightweight panels with clips and screws rather than mortar.

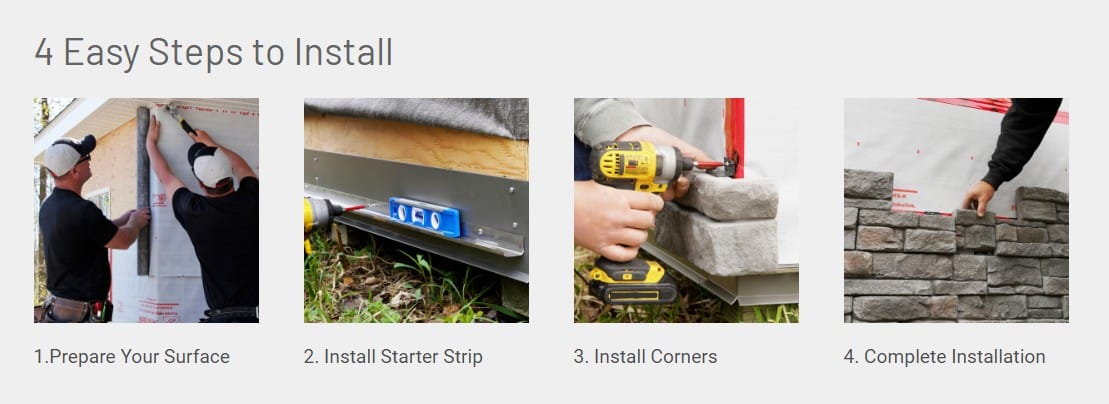

For example, the Eldorado Stone CONNECT System uses a straightforward installation process: panels lock into place using a metal starter strip and fastening clips. The result is a simple, efficient method that does not require specialized tools or highly skilled masons.

The CONNECT System Installation

Fusion Stone Installation Steps

Benefits of Mechanically Fastened Veneer Panels

Faster Installation

Mechanically fastened veneer installs up to ten times faster than full masonry. The TIER Panel System can cover 300 sq/ft in a single day compared to about 32 sq/ft using traditional methods. That means days saved on labour and weeks off project timelines.

Simple Installation Without Specialists

Masonry requires skilled masons, but veneer systems are designed so general contractors or experienced DIYers can handle the work with standard tools. This opens up masonry-style finishes to more projects where masons are unavailable.

Predictable Project Costs

Labour, weather delays, and specialized skills can make masonry costs unpredictable. Veneer panels shorten install time and reduce labour requirements, delivering more consistent and manageable budgets.

Lightweight Panels for Easier Renovations

Panels weigh far less than full-bed stone or brick. They attach to existing structures without structural reinforcement, making them ideal for remodels, modular construction, or retrofits where weight is a concern.

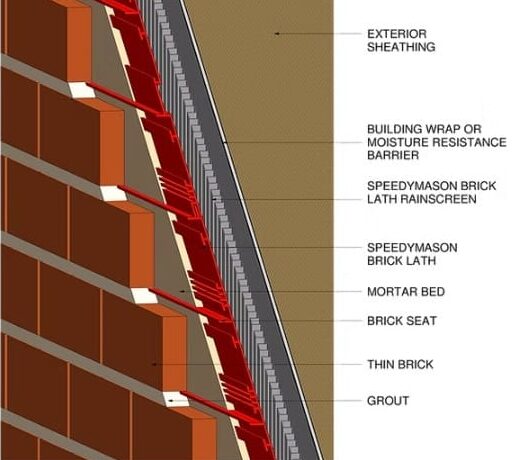

Built-In Rainscreen for Moisture Protection

Each system includes an air gap that acts as a rainscreen. This feature manages airflow and drainage, protecting structures from moisture buildup and improving performance in wet or snowy

climates.

Speedymason Brick Lath Rainscreen

Applications: Indoors and Outdoors

Contractors and homeowners choose mechanically fastened veneer for efficiency and design versatility. Available in a wide range of colours, textures, and finishes, these panels bring masonry aesthetics to projects where full stone or brick would be too heavy, costly, or time-intensive.

Indoors:

- Fireplaces – Panels create the warmth of stone or brick without the weight or need for structural reinforcement.

- Accent walls – Add texture and contrast to feature walls in living rooms, dining areas, or offices.

- Kitchen backsplashes – Achieve a durable masonry look that installs faster than tile and resists heat and splashes.

- Staircases – Lightweight panels make vertical surfaces easier to clad without major framing work.

- Columns and pillars – Veneer panels wrap existing posts to give them the look of solid stone.

Black River Stacked Stone | The CONNECT System

Outdoors:

- Facade cladding – Ideal for new builds or retrofits where traditional stone would require added structural support.

- Retaining walls – Create a finished look while using a mechanically fastened system that speeds up installation.

- Outdoor kitchens – Panels withstand rain, snow, and UV exposure while reducing installation costs.

- Water features – Provide a natural stone appearance in areas where full stone would be too heavy.

- Backyard fireplaces – Deliver the look of a traditional masonry build in a fraction of the time.

Performance in Real Conditions

- Ease of installation: Most projects are planned, purchased, and completed within a single day. Maintenance and replacements are also simple.

- Cost savings: Savings are realized at every stage, from materials to installation time and labour.

- Weather resilience: Mechanically fastened systems work in wet or dry conditions, reducing weather delays.

- Design flexibility: These systems make small or complex projects, such as corner fireplaces or compact backsplashes, much more feasible.

Myths About Mechanically Fastened Systems

Myth: It Looks Fake

Fact: Early manufactured stone products created the impression that veneer looked fake. Modern options solve this. Natural thin stone veneer is cut directly from quarried stone, while manufactured veneer is made from a blend of Portland cement, lightweight aggregates, and iron oxide pigments, then shaped for authentic texture and colour variation. The result is a masonry look that’s virtually indistinguishable from full stone or brick.

Myth: It Doesn’t Last

Fact: Lightweight design often raises durability concerns, but mechanically fastened systems are engineered for long-term performance. They are tested for freeze-thaw cycles, impact resistance, and compliance with building codes, and many carry manufacturer warranties. Their modular nature also allows individual panels to be replaced without major repairs.

Myth: It Can’t Withstand Harsh Weather

Fact: Panels are designed to resist moisture infiltration, UV damage, and temperature swings. The built-in rainscreen system ensures proper drainage, preventing water buildup behind the panels. This makes mechanically fastened veneer particularly effective in climates with heavy rain, snow, or freeze-thaw cycles.

Traditional Masonry vs. Veneer Systems

Both traditional masonry and mechanically fastened veneer have their place. For load-bearing walls, heritage restoration, or projects where craftsmanship is the priority, masonry is the best option.

For projects where speed, versatility, and cost control are essential, mechanically fastened systems are often the more practical choice. Rather than replacing masonry, veneer systems serve as a complementary option that expands design possibilities.

Find the Right Mechanically Fastened System for Your Project

At I-XL, you can explore a wide selection of mechanically fastened systems from Eldorado Stone, TIER, Fusion Stone, and Speedymason. Find the right system for your project or connect with our team for expert guidance.